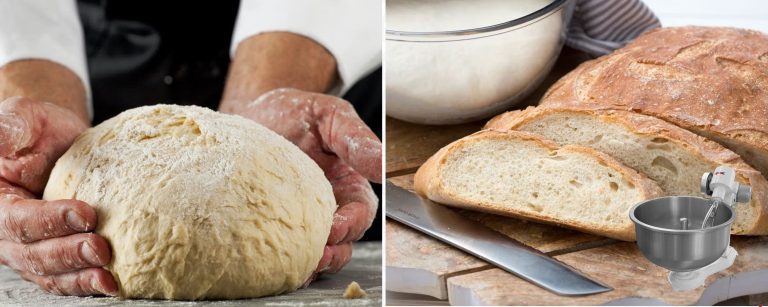

Every day at noon in the kitchen of a busy restaurant, everything moves quickly and energetically. The tables are full of orders and time is short. The head chef glances at his employee who is still busy kneading the dough by hand; hands that have become numb from the hard work and the speed of work has slowed down. Sometimes, the quality of the bread is inconsistent, which causes customer dissatisfaction. At that moment, the head chef asks himself: Is there a way to make this tiring and error prone process faster and more professional? Is it possible to have the best dough prepared in the shortest time with minimal effort?

Kneading dough by hand is an old and challenging art. In today’s kitchens where speed and quality are paramount, this method no longer meets modern needs. Manual kneading not only consumes a lot of energy from the staff but also results in inconsistent dough quality. This fatigue over time causes decreased efficiency, more errors, and even physical injuries. The head chef and his team know that continuing this process means lost opportunities, decreased customer satisfaction, and limited production capacity.

But there is a simple and effective solution: a machine that can knead dough several times faster, without fatigue, and with consistent, professional quality. The industrial dough kneader provides the possibility that the workforce gets less tired while significantly increasing the volume and quality of the product.

This machine, with its special design and powerful motors, kneads the dough in the best possible way, just as you need it. You no longer have to worry about inconsistent dough quality, because every time the dough is prepared with perfect uniformity and elasticity. The high speed of this machine allows you to prepare much larger quantities of dough for baking in less time; something that can guarantee the success of your business.

But why is dough quality so important? Dough is the foundation of bread and every baked product. If the dough is not kneaded properly, the final product either becomes tough, fails to rise well, or lacks the right texture and taste. This means customers looking for quality may no longer return to you. On the other hand, having dough with excellent and consistent quality can lead to customer loyalty and positive word of mouth advertising.

When considering choosing an industrial dough kneading machine, you should pay special attention to features like suitable capacity for your production needs, sufficient motor power, durability and build quality, ease of use, and after sales service. Making the right choice is not only a financial investment but also a smart step towards professional development and growth.

Among the brands, KiTech, with a long history in manufacturing industrial kitchen equipment, offers machines built according to international standards and equipped with modern technologies. KiTech not only guarantees the quality and durability of its machines but also provides specialized after-sales support and services for its customers.

You might ask, “Is using an industrial dough kneading machine complicated?” The answer is no. These machines are designed so that even those with little experience in working with industrial equipment can easily operate them. Simple controls, adjustable speed and kneading time, and a body that is easy to clean all contribute to a pleasant user experience.

If your business seeks to increase productivity and reduce costs, this machine can be considered a smart investment. Reducing the human labor required for kneading dough and increasing production speed means lower operational costs and higher profitability.

With KiTech, you can be assured of receiving a machine with the best quality and after-sales service. This brand is always alongside its customers, helping them choose the right machine and supporting them after purchase.

Right now, you can visit KiTech’s website to view different models of industrial dough kneading machines or contact sales experts for specialized guidance.

It’s time to say goodbye to the old and time-consuming manual dough kneading methods and take your speed, quality, and productivity to the next level with KiTech.

Industrial dough kneading machine

- Industrial potato peeler

- Automatic potato peeling machine

- Potato peeler for export

- High quality potato peeling equipment

- Potato peeling machine manufacturer

- Export potato peeler machine

- Commercial potato peeler

- KiTech potato peeling machine